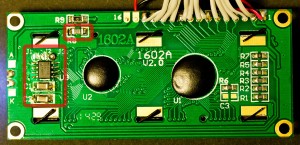

Some LCD modules have unpopulated footprints on the back (see Photos 1 and 2). Usually these pads are for ICL7660 (MAX660, MAX1044, or compatibles), a switched-capacitor voltage converter. This post is to attempt installation of MAX660 on dirt cheap 5V LCD modules and 3.3Vizing them.

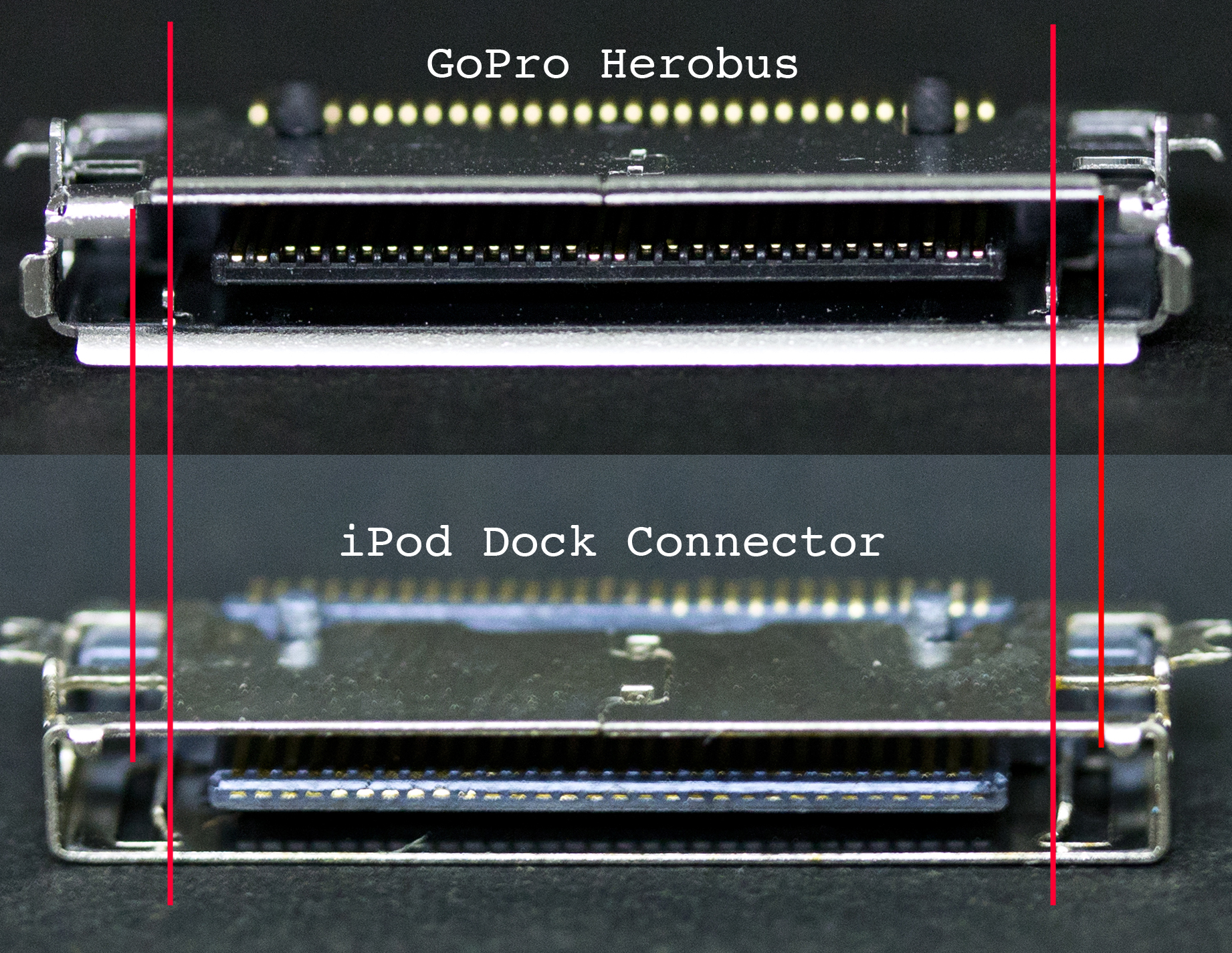

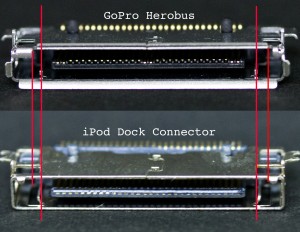

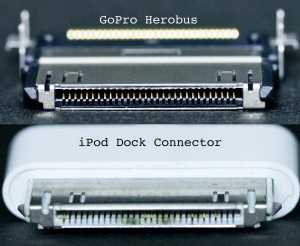

Note: The article is nothing to do with GoPro. This is related to our another project “NFC tags for schools”. A summary of the product will be shown at the end of post.

⇧ Photo 1: HJ1602A, Shen Zhen Huijing Technology Co., Ltd (cn: 深圳绘晶科技有限公司) [395JPY at Aitendo, Tokyo, Japan]

⇧ Photo 2: Seed Studio LCD104B6B or TOPWAY LMB0820D [570JPY at Sengoku Densyo (ja:千石電商), Tokyo, Japan]

1. Why 3.3V?

These days many devices are working on 3.3V or even on 1.8V, for example, GoPro is on 3.3V, and Intel Edison is on 1.8V. However, liquid crystal displays (LCDs) are usually on 5V, because they are made out of 1980s’ technology due to Hitachi’s de facto standard LCD controller chip HD44780.

Thus there are many sites explaining 3.3Vizing of LCDs, for example,

- Using Character LCD module at 3 volts; a perfect explanation

- Using a 5V CG LCD in a 3.3V design

The latter author did a very similar thing to the current article (i.e., he mounted ICL7660 to another LCD). So I’m afraid this post might be a kind of “reinventing the wheel”, but writing this now because it might be useful to someone especially who can actually go and buy these LCDs in Tokyo.

2. Experiment

It seems that HJ1602A (Photo 1) is sometimes sold with ICL7660 mounted. Fortunately we can find such a photo at Magyar site (see “6_2. ábra”). So the LCD is very easy to 3.3Vize as in the following picture:

⇧ Photo 1′: Mounting MAX660 to 3.3Vize HJ1602A

Note: U3=MAX660, C1=C2=10uF, J1=J2=open, J3=close, R8=330 (R8 for back light current restriction at 3.3V)

For LMB0820D (Photo 2) we haven’t yet found any picture on the Net with ICL7660 mounted. But we have already learned how to mod it from two examples above:

⇧ Photo 2′: Mounting MAX660 to 3.3Vize LMB0820D

Note: U2=MAX660, C2=C3=10uF, R6=R7=10k, R8=75k, R10=560 (R10 for back light current restriction at 3.3V), JP5=JP8=close (for enabling back light)

3. Results

Here are the results of mods:

⇧ Photo 1″: HJ1602A at 3.3V

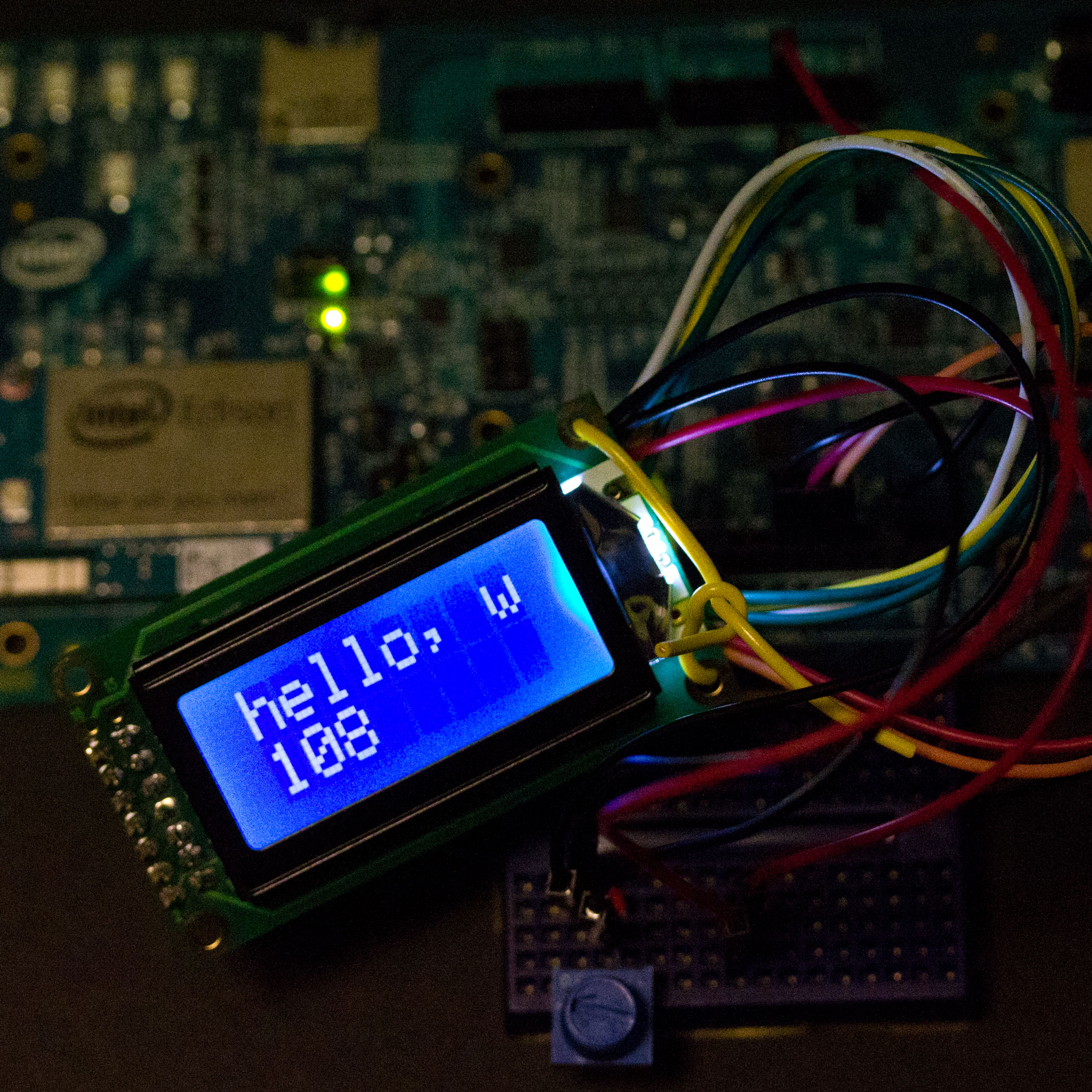

These are worked on Intel Edison Arduino Board set 3.3V and/or Intel Edison Breakout Board with FXLA108, a dual-supply 8-bit signal translator.

PR: NFC tags for schools

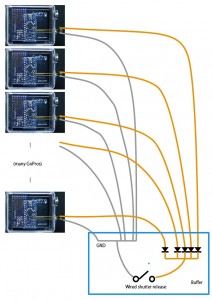

At the beginning of the current project we like to vet some usable LCDs for our purpose: an electrical roll book for schools. The roll book device is required to be able to:

- Communicate with Google Spreadsheet through 5GHz Wi-Fi network (for uploading attendance/absence records and downloading the list of registered students)

- Read NFC tags embedded in student ID cards

- Show results instantly while scanning an ID

Aiming these we have decided to use Intel Edisons for the CPU and Sony RC-S380 for the card reader. And then we came to choose one more item, some brand of low cost LCD works on 3.3V.

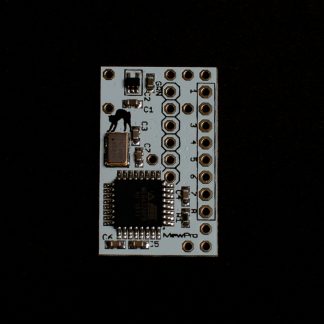

⇧ Prototype of our Electrical Roll Book Device: Intel Edison (left), 3.3V LCD (right), Sony NFC reader (bottom)

This device is nearly completed by now, and one unit of system is fixed to be delivered to a collage in Shizuoka, Japan.